Wire Mesh Weaving

Wire mesh weaving is a process used to produce woven wire mesh from various materials such as stainless steel, brass, copper, and other alloys. In this process, a series of interlocking wires are woven together to create a mesh pattern. The weaving can be done manually or through automated machines.

The wires used in the weaving process can vary in diameter and thickness, depending on the desired mesh size and strength. The weaving process can produce a range of mesh types, including plain weave, twilled weave, and Dutch weave.

A plain weave is the simplest type of weave, where the wires cross over and under one another at right angles to one another. In twilled weave, each wire passes over and under several wires to create a diagonal pattern. Dutch weave is like plain weave, but it involves using thicker wires in the weft and thinner wires in the warp to create a tighter mesh structure.

Wire mesh weaving is used in a variety of applications, including filtration, screening, and separation. It is commonly used in industries such as mining, oil and gas, food and beverage, and construction.

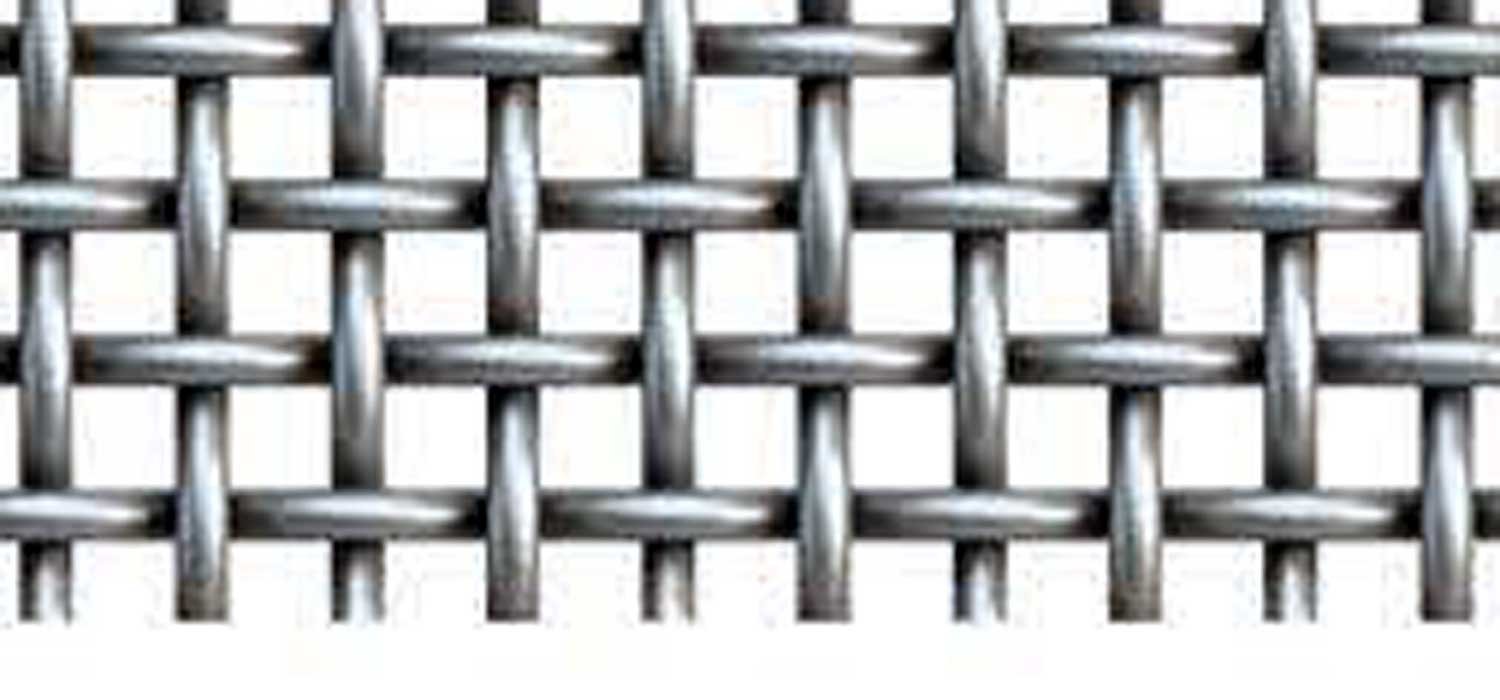

Square Mesh

This is the most common type of wire mesh weave, where wires are woven over and under each other to create a square-shaped opening. Square mesh is widely used in a variety of applications, such as filtration, screening, and fencing.

Twill Mesh

Twill mesh is created by weaving wires over and under two or more adjacent wires, creating a diagonal pattern. This type of weave is commonly used in applications that require extra strength and stability, such as industrial filtration.

Plain Dutch

Plain Dutch weave involves weaving thicker wires in one direction and thinner wires in the other direction to create a tight weave with small openings. This type of weave is commonly used in applications that require high precision and accuracy, such as aerospace and medical industries.

Twill Dutch

Twill Dutch weave is like Plain Dutch weave, but the wires are woven in a diagonal pattern to create larger openings. This type of weave is commonly used in applications that require high flow rates and good particle retention, such as oil and gas filtration.

Hollander Weave

Hollander weave is a type of Plain Dutch weave where the wires are woven more tightly in one direction than the other. This type of weave is used in applications that require a high degree of accuracy and stability, such as particle size analysis and scientific research.